What is Amazon Robotic Fulfilment Center?

The aim of the gigantic Amazon’s robotic fulfillment centers is to speed up delivery of products by using robots for certain tasks, such as moving shelves to employees to reduce picking time for orders.

Although there is a human element involved the Amazon Robotic Fulfilment Centers , these are in large parts warehouses operated by different kinds of robots.

Where are Amazon Robotic Fulfilment Centers located?

The robotic fulfillment centers are located strategically across the US as well as Europe. For example in Ohio in the United States the warehouse is over 65 00 square meters (700 000 sq ft).

What kind of robots and devices can we find in the Amazon Robotics Fulfilment Center?

There is a lof of technology that is working behind the scenes in Amazon warehouses and much of it may not be visible at first sight. Most of the technologies used are proprietary and something that Amazon has been working on for long time.

The time to fulfill the order must be minimized. Lets review below some of the robotic masterpieces and devices in the warehouse that support this big goal.

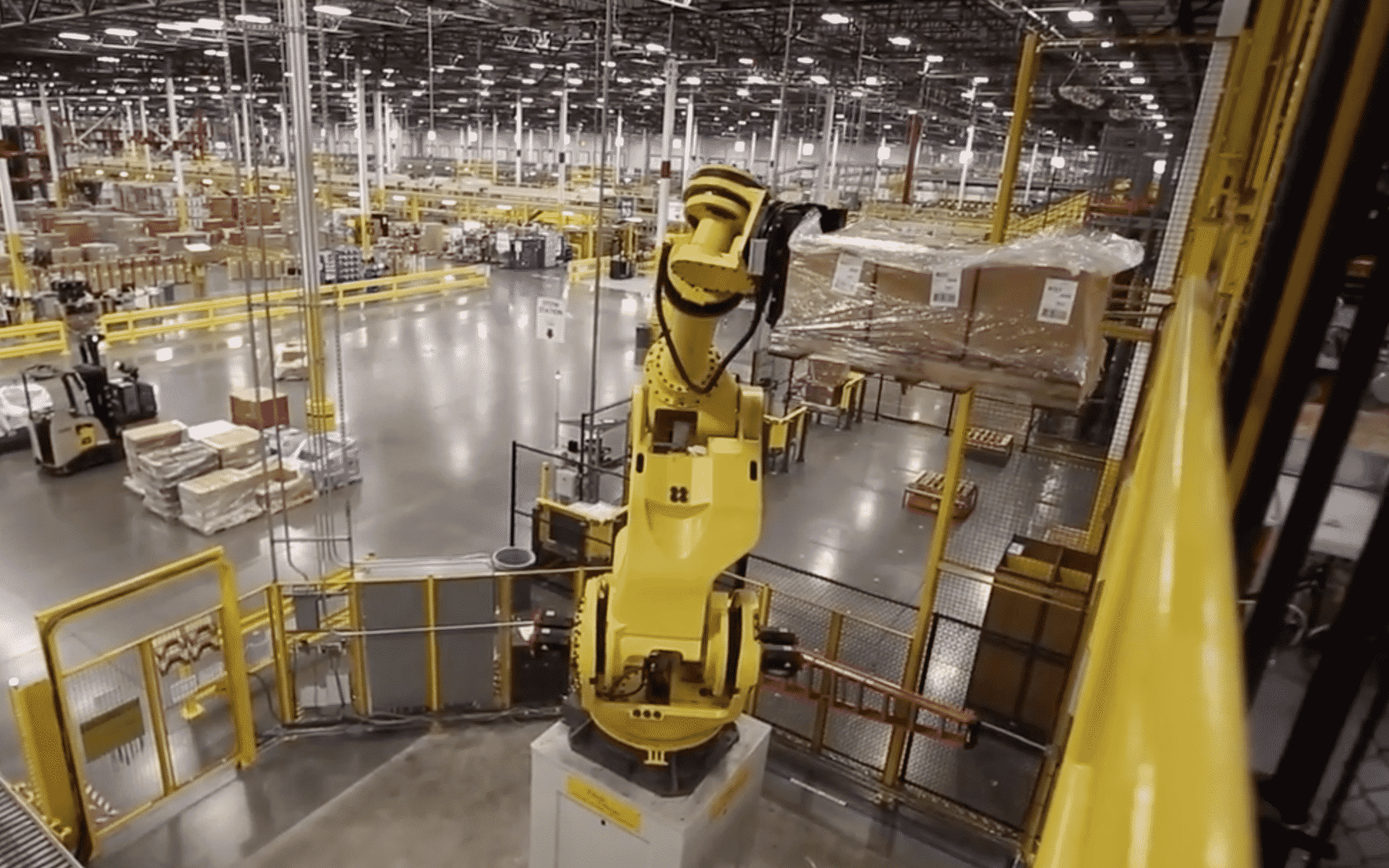

Fanuc 6 axis robot

Fanuc 6 axis robot is a massive robotic arm that can lift 1300 kg (3000 pound) pallets 7m (24 ft) in the air. It can be found for example in the Dupont, WA, Amazon 8th Generation Fulfilment Center.

Robotic Drive Unit

Robotic Drive Unit from Amazon Robotics (formerly KIVA), the maker of mobile robotic fulfillment systems, carries inventory pods. Slow frequency pods are usually kept backward, high frequency pods are kept nearer.

Mobile Inventory Pod and Order Pod

Inventory pods are carried by the robots to the picking stations. Workers pick items and put them to order pod. This then moves to shipping after fulfilling all orders.

Employee Robotic Safety Vest

The safety vest is designed to work in tandem with the robots’ existing obstacle avoidance detection.

Hydrogen-fueled forklifts

In the new Amazon warehouse in Schodack you can find hydrogen-fueled forklifts whirring back and forth between vast rows of 30-foot-high shelves.

Box on Demand

Box on Demand is a machine, which based on the scanned shape and dimension of an item will spit out a custom-sized box that fits perfectly for the product. According to PC Magazine, each robot packer can handle up to 700 orders per hour. One robot at a warehouse means 24 human roles are no longer required. This solution also saves trucking costs as well as packaging material. Each robot packer costs $1 million plus running expenses but Amazon recoups the money spent in just two years.

Flat-screen displays

In Schodack fulfillment center you can find large flat-screen displays all around the floor. These indicate whether you are within 6 feet of another person.

Amazon warehouse security features

On the front of buildings, there are typically locked doors, with entry keypads. Often the window panes are smoked glass, with nothing visible inside.

During the Corona-19 crises, warehouses introduced also overhead temperature scanners that check incoming workers and visitors, who enter through several lanes, similar to airline security checks.

The drivers of hydrogen forklifts are strapped into overhead beams, giving them the appearance of spacemen. The drivers are in safety harnesses that ensure they would be caught should they slip off the forklift deck as it rises 20 or 30 feet up to grab items off the top shelves.